How Do Twisted Pair Cables Work?

Feb 20, 2025

Leave a message

I think many people have asked such a question: How Do Twisted Pair Cables Work? We all know that twisted pair is a transmission medium composed of two insulated copper conductors twisted together.

A twisted pair typically consists of two 22–26 gauge insulated copper wires twisted together, with each wire's insulation layer marked in different colors. When one or more pairs of twisted wires are enclosed within an insulated sheath, they form a twisted pair cable. Twisted pair cables are classified into two main types: unshielded twisted pair (UTP) and shielded twisted pair (STP). The operating principle involves twisting two insulated copper wires together at a specific density. When electromagnetic waves are emitted, the waves radiated by each wire cancel each other out, significantly reducing signal interference. Twisted pair cables can be configured as either straight-through or crossover cables. Straight-through cables require both ends of the cable to follow the same wiring standard, while crossover cables use different wiring standards at each end. When producing twisted pairs, two wiring standards are typically followed depending on the required sequence: ANSI/EIA/TIA-568A and ANSI/EIA/TIA-568B . Twisted pairs have certain limitations in terms of transmission distance, channel bandwidth, and data transfer speed but are relatively inexpensive. Performance metrics include attenuation, near-end crosstalk, impedance characteristics, distributed capacitance, and DC resistance. Although twisted pairs were originally used for transmitting analog signals, they are now widely used for digital signal transmission as a common cabling material.

To reduce mutual interference between the two wires and mitigate electromagnetic phenomena caused by current flow, the wires are twisted together.

Basic Information

English Name: Twisted Pair

Category: Information communication network transmission medium

Application: Cabling material

Composition: Two insulated copper conductors of 22–26 gauge twisted together

Function: Minimizes signal interference

English Name: Twisted Pair

Category: Information communication network transmission medium

Application: Cabling material

Composition: Two insulated copper conductors of 22–26 gauge twisted together

Function: Minimizes signal interference

1. Principle Explanation About How Do Twisted Pair Cables Work

A twisted pair consists of a pair of mutually insulated metal conductors twisted together. This design not only resists some external electromagnetic interference but also reduces mutual interference among multiple pairs of wires. When two insulated conductors are twisted together, any interference signal affecting these intertwined conductors is identical (this interference signal is called a common-mode signal). In differential circuits that receive signals, common-mode signals are canceled out, allowing useful differential-mode signals to be extracted.

The purpose of a twisted pair is to ensure that external interference generates identical noise on both conductors so that subsequent differential circuits can extract useful signals. A differential circuit acts as a subtractive circuit where in-phase signals at its inputs (common-mode signals) cancel out (m-n), while opposite-phase signals behave as x-(-y), resulting in amplification. Theoretically, in a twisted pair and differential circuit setup where m=n and x=y, interference signals are completely canceled out while useful signals double in strength; however, there are some discrepancies during actual operation.

Within a single cable sheath, different wire pairs have varying twist lengths. Generally speaking, twist lengths range from 38.1 mm to 140 mm and are typically twisted in a counterclockwise direction; the twist length difference between adjacent wire pairs is within 12.7 mm. The length of one twist cycle in a twisted pair is called its pitch; shorter pitches result in stronger anti-interference capability.

2. Twisted Pair Cables'Classification Overview

Shielding Layer Types

Distinction Between Shielded and Unshielded Twisted Pairs.

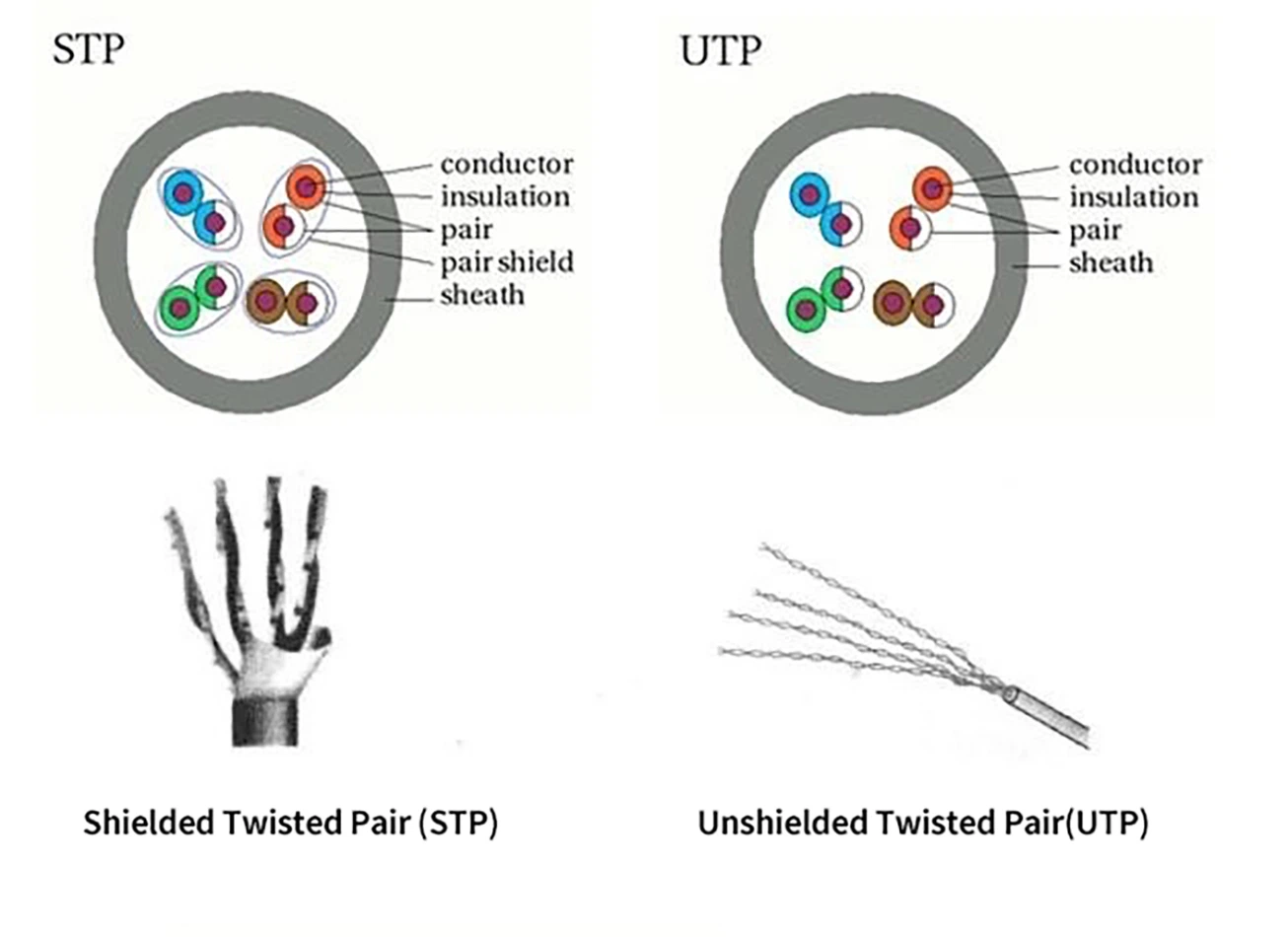

Based on the presence or absence of a shielding layer, twisted pair cables are categorized into Shielded Twisted Pair (STP) and Unshielded Twisted Pair (UTP).

Shielded twisted pair cables feature a metal shielding layer between the twisted pairs and the ethernet cable jacket. They are further divided into STP and FTP (Foil Twisted Pair). STP refers to cables where each pair has its own shielding layer, while FTP has a single shielding layer for the entire cable, which functions effectively only when both ends are properly grounded. This necessitates an entirely shielded system, including cables, outlets, connectors, and patch panels, as well as a robust grounding system in the building. The shielding layer reduces electromagnetic radiation and prevents information leakage while blocking external electromagnetic interference, enabling shielded twisted pairs to achieve higher transmission rates compared to unshielded counterparts.

Unshielded Twisted Pair (UTP) is a type of data transmission cable composed of four pairs of differently colored wires. It is widely used in Ethernet networks and telephone lines. UTP cables offer several advantages:

No shielding jacket, compact design, space-saving, and cost-effective.

Lightweight, flexible, and easy to install.

Reduces or eliminates crosstalk.

Offers flame-retardant properties.

Independent and versatile, suitable for structured cabling systems.

Consequently, UTP is extensively used in structured cabling systems.

Consequently, UTP is extensively used in structured cabling systems.

3.Frequency and Signal-to-Noise Ratio

Twisted Pair Cables

The most commonly used types of twisted pair cables include Category 3 (CAT3), Category 5 (CAT5), Enhanced Category 5 (CAT5e), and Category 6 (CAT6). Earlier categories have thinner cable diameters compared to later ones with thicker diameters. Specific models are described as follows:

1) Category 1 (CAT1):

Maximum frequency bandwidth is 750kHz; commonly used in alarm systems or legacy telephone wiring before the early 1980s. Not suitable for data transmission.

2) Category 2 (CAT2):

Maximum frequency bandwidth is 1MHz; frequently used for voice transmission and data transfer speeds up to 4Mbps, often found in older Token Ring networks adhering to the 4Mbps Token Passing protocol.

3) Category 3 (CAT3):

Defined by ANSI and EIA/TIA568 standards with a transmission frequency of 16MHz and a maximum transmission rate of 10Mbps (10Mbit/s). Primarily applied in voice communication, 10Mbit/s Ethernet (10BASE-T), and 4Mbit/s Token Ring networks with a maximum segment length of 100m using RJ connectors. This category has largely been phased out.

4) Category 4 (CAT4):

Transmission frequency is 20MHz; used for voice communication and data transfer at speeds up to 16Mbps, such as in Token Ring LANs or for 10BASE-T/100BASE-T networks. Maximum segment length is 100m using RJ connectors but was never widely adopted.

5) Category 5 (CAT5):

Features increased wire twisting density with a high-quality insulating jacket. The maximum frequency bandwidth is 100MHz with a maximum data transfer rate of 100Mbps, supporting voice communication as well as data networks like 100BASE-T and 1000BASE-T Ethernet with a maximum segment length of 100m using RJ connectors. This remains one of the most commonly used Ethernet cable types today.

6) Enhanced Category 5 (CAT5e):

Offers reduced attenuation, minimized crosstalk, higher attenuation-to-crosstalk ratio (ACR), improved signal-to-noise ratio (SNR), and lower delay skew compared to CAT5 cables-delivering significantly enhanced performance. CAT5e cable is primarily utilized in Gigabit Ethernet applications (1000Mbps).

7) Category 6 (CAT6):

Transmission frequency ranges from 1MHz to 250MHz. The CAT6 cables offers improved margins for overall power sum attenuation-to-crosstalk ratio (PS-ACR) at frequencies up to 200MHz-providing double the bandwidth of CAT5e cables. CAT6 far exceeds CAT5e standards in terms of performance and is ideally suited for applications requiring speeds greater than 1Gbps. A key difference between CAT6 and CAT5e lies in its enhanced performance against crosstalk and return loss-critical factors for next-generation full-duplex high-speed network applications. The CAT6 standard eliminates the basic link model; instead, it specifies a star topology structure with wiring distance requirements: permanent link lengths cannot exceed 90m, while channel lengths must not exceed 100m.

8) Augmented Category 6 or CAT6A:

Transmission bandwidth of CAT6a cables falls between CAT6 and CAT7 at frequencies up to 500MHz with transfer speeds reaching up to 10Gbps; standard outer diameter is approximately 6mm. Similar to CAT7 products, no formal national testing standards currently exist-only industry-declared specifications from manufacturers.

9) Category 7 (CAT7):

Transmission frequency of CAT7 cables reaches up to 600MHz with transfer speeds up to 10Gbps; the standard outer diameter is approximately 8mm for single-core cables and approximately 6mm for multi-core cables.

Higher category numbers and newer versions indicate more advanced technology-offering broader bandwidth capabilities but also higher costs associated with them. These different types of twisted pair cables are designated by standardized markings: standard types are labeled "CATx," such as commonly used CAT5 or CAT6 marked on their outer jackets as "CAT5" or "CAT6." Improved versions follow an "xe" labeling convention-for example "CAT5e" indicates Enhanced Category 5 cable ("e" being lowercase rather than uppercase).

Regardless of the network cable type chosen, attenuation increases proportionally with rising frequencies during usage. Cabling infrastructure design must ensure that signal amplitude remains sufficient at receiving ends-even under noisy environmental conditions-to enable accurate detection amidst interference… Additionally, achievable data speeds depend heavily on the digital encoding methods employed within system architecture configurations!

4. Wiring Sequence Standards

ANSI/EIA/TIA-568A, ANSI/EIA/TIA-568B

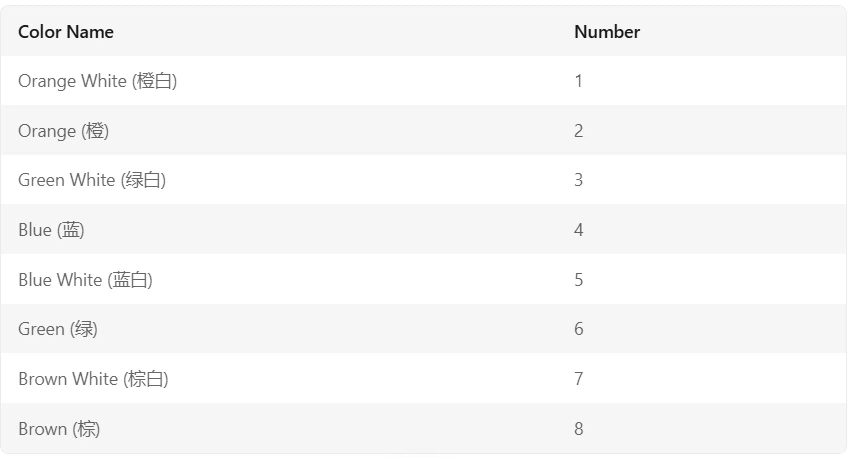

In North America and internationally, the three most influential organizations in structured cabling are as follows: ANSI (American National Standards Institute), TIA (Telecommunication Industry Association), and EIA (Electronic Industries Alliance). Since TIA and ISO (International Organization for Standardization) frequently collaborate on standard development, the differences between the standards they publish are minimal. In North America and globally, the most widely adopted twisted-pair wiring standards are ANSI/EIA/TIA-568A and ANSI/EIA/TIA-568B (technically ANSI/EIA/TIA-568B.1, commonly referred to as T568B). The primary distinction between these two standards lies in the sequence of wire pairs (refer to the table below):

In North America and internationally, the three most influential organizations in structured cabling are as follows: ANSI (American National Standards Institute), TIA (Telecommunication Industry Association), and EIA (Electronic Industries Alliance). Since TIA and ISO (International Organization for Standardization) frequently collaborate on standard development, the differences between the standards they publish are minimal. In North America and globally, the most widely adopted twisted-pair wiring standards are ANSI/EIA/TIA-568A and ANSI/EIA/TIA-568B (technically ANSI/EIA/TIA-568B.1, commonly referred to as T568B). The primary distinction between these two standards lies in the sequence of wire pairs (refer to the table below):

The wire sequence for EIA/TIA 568A is defined as green-white, green, orange-white, blue, blue-white, orange, brown-white, brown.

The wire sequence for EIA/TIA 568B is defined as orange-white, orange, green-white, blue, blue-white, green, brown-white, brown.

According to the 568A and 568B standards for RJ45 connectors (commonly referred to as modular plugs), each contact point in network connections plays a specific role in signal transmission: pins 1 and 2 are used for sending signals; pins 3 and 6 are used for receiving signals; pins 4 and 5, as well as pins 7 and 8, serve as bi-directional lines. For the twisted-pair cables connected to them, to reduce mutual interference, the standards require that pins 1 and 2 must form a twisted pair; pins 3 and 6 must also form a twisted pair; pins 4 and 5 should be twisted together; pins 7 and 8 should also be twisted together. This demonstrates that there is no fundamental difference between the two standards-568A and 568B-other than the arrangement of the eight wires when connecting to an RJ-45 connector. In practice, however, the 568B standard is more commonly used in network engineering projects.

5. Production Steps

Below is an introduction to the basic method for making straight-through Cat5 cables. The production methods for other types of network cables are similar; only the crossover configurations differ.

Step 1: Use a pair of twisted-pair cable crimping tools (or other cutting tools) to trim one end of a Category-5 cable evenly. First cut a length of cable that meets your wiring requirements. Place the trimmed end into the stripping slot of the crimping tool while ensuring that the cable remains straight without bending.

Step 2: Gently grip the crimping tool and slowly rotate it once around the cable. There's no need to worry about damaging the inner core wires because there's a gap between the blades specifically designed for stripping-this gap typically matches the diameter of four pairs of core wires inside. This action will slice through the outer protective sheath of the twisted-pair cable. Remove this sheath manually or with a specialized stripping tool. Note: The length of stripped cable should be approximately 15mm-the same length required to fit properly into an RJ45 connector-to avoid issues caused by over-stripping or under-stripping. Over-stripping not only looks untidy but may also cause loose connections because it prevents proper clamping by the connector; under-stripping leaves too much sheathing material at insertion points, preventing full insertion into an RJ45 connector.

Step 3: After removing the outer sheath from one end of your cable segment using these techniques, you will see four pairs of twisted wires inside with distinct color patterns: brown paired with brown-white; orange paired with orange-white; green paired with green-white; and blue paired with blue-white.

Step 4: Untangle each pair of intertwined wires one by one. After untangling, arrange and align the groups of wires in order according to the guidelines. While arranging, try to avoid excessive tangling and overlapping. Once the wires are arranged and straightened, they may have some bends due to being previously intertwined. Grasp the wire with both hands, pull firmly in opposite directions, and gently tug it up and down to straighten it as much as possible while keeping it flat.

Step 5: After arranging, straightening, and flattening the wires, carefully inspect them thoroughly once more. Then, use the cutting blade of a crimping tool to neatly trim the ends of the wires.

Step 6: Insert the neatly arranged wires into an RJ45 connector. Ensure that the side of the connector with the plastic spring clip faces downward while the side with pins faces upward, with the pin end pointing away from you and the rectangular opening facing toward you. At this point, pin 1 is on the far left, pin 8 is on the far right, and all others are sequentially aligned in between. When inserting, gently push all eight wires simultaneously into their respective grooves inside the RJ45 connector until they reach the end of their slots. Ensure horizontal alignment during insertion; otherwise, uneven wire lengths may disrupt proper contact between the wires and connector. If you previously stripped off too much protective insulation, trim any excess here so that approximately 15mm of exposed wires remain-this is just enough for each wire to fit snugly into its designated groove. Leaving this section too long can increase crosstalk due to untwisted wires or cause poor contact or disconnection if the connector fails to clamp onto the protective jacket properly. Before proceeding to crimping in the final step, check from above through the RJ45 connector to confirm that each wire is securely seated at its endpoint.

Step 7: Crimping. Before proceeding with this final crimping step, inspect from above through the RJ45 connector once again to confirm that each wire is securely seated at its endpoint. Once verified, insert the RJ45 connector into the 8P slot of a crimping tool for crimping. After inserting it into place, firmly squeeze the crimping tool handles together; if more force is needed, use both hands for added pressure. When you press hard enough, all external pins on the RJ45 connector will be fully pressed into their respective slots inside it. You should hear a faint "click."

Step 8: After crimping, all external pins on the RJ45 connector should be completely pressed into their respective slots inside it. Additionally, the plastic locking tab at the base of the RJ45 connector should be firmly clamped onto the gray protective jacket of the network cable. Now your RJ45 connector assembly is complete.

6. Performance Indicators

For twisted-pair cables, users are primarily concerned with several indicators that define their performance. These include attenuation, near-end crosstalk (NEXT), impedance characteristics, distributed capacitance, DC resistance, and others.

1) Attenuation

Attenuation measures the degree of signal loss along a link. It is directly related to the length of the cable-signal attenuation increases as the length increases. Attenuation is measured in decibels (dB) and represents the ratio of signal strength at the transmission end to that at the receiving end. Since attenuation varies with frequency, it should be measured across all frequencies within the application range.

2) Near-End Crosstalk (NEXT)

Crosstalk can be categorized as near-end crosstalk (NEXT) or far-end crosstalk (FEXT). Test equipment primarily measures NEXT because FEXT is less significant due to line loss. NEXT quantifies the signal coupling from one wire pair to another within an unshielded twisted-pair (UTP) cable link. For UTP links, NEXT is a critical performance indicator and one of the most challenging metrics to measure accurately. As signal frequency increases, measurement difficulty rises.

NEXT does not represent the actual crosstalk generated at the near-end point; it only reflects the value measured at that point. This value varies with cable length-longer cables result in smaller values as signals at the transmission end attenuate, reducing crosstalk on other pairs accordingly. Experiments show that NEXT measurements taken within 40 meters are more reliable. If one end of the cable exceeds 40 meters from an information outlet, some degree of crosstalk may occur but might not be accurately detected by test equipment. Therefore, it is best to measure NEXT at both endpoints. Most testing devices can measure NEXT values for both endpoints from a single location.

The results of NEXT tests can be referenced against:

Attenuation limits for various twisted-pair connections at maximum length across different frequencies.

NEXT attenuation limits at specific frequencies.

These two indicators form the core content of TSB67 testing; however, certain tester models can also provide additional parameters such as DC resistance, characteristic impedance, and attenuation-to-crosstalk ratio (ACR).

3) DC Resistance

DC loop resistance consumes part of the signal by converting it into heat energy. It refers to the combined resistance of both wires in a pair. According to 11801 standards, DC resistance for twisted-pair cables must not exceed 19.2 ohms. Differences between pairs should be minimal (less than 0.1 ohms); larger differences indicate poor contact points that need inspection.

4) Characteristic Impedance

Unlike DC loop resistance, characteristic impedance includes resistance as well as inductive and capacitive reactance over frequencies ranging from 1 MHz to 100 MHz. It depends on factors like conductor pair spacing and the dielectric properties of their insulation material. Different cables exhibit varying characteristic impedances; twisted-pair cables commonly have values such as 100 ohms, 120 ohms, or 150 ohms.

5) Attenuation-to-Crosstalk Ratio (ACR)

ACR, within specific frequency ranges, represents an important parameter of cable performance-the ratio of attenuation to crosstalk levels. ACR is sometimes expressed as Signal-to-Noise Ratio (SNR) and is calculated as the difference between worst-case attenuation and NEXT values. Higher ACR values indicate stronger interference immunity; generally, systems require ACR values exceeding 10 dB.

6) Cable Characteristics

The quality of a communication channel is defined by its cable characteristics. SNR measures data signal strength while accounting for interference signals. If SNR falls too low, receivers may fail to differentiate data signals from noise, leading to errors in data transmission. To minimize these errors and ensure reliable communication, a minimum acceptable SNR must be defined.

7. Major Brands

1) AMP

AMP is the most common and widely used brand in China. It is available in almost every network cable retail store. Its biggest advantages are good quality and low price. However, due to its popularity, some counterfeits are so convincing that they can hardly be distinguished from the real product.

AMP's Category 6 twisted pair system consists of Quantum UTP cables, Quantum modular information outlet systems, Quantum modular patch panel systems, and Quantum patch cords. The Quantum Category 6 system provides a bandwidth of 200 MHz, with its UTP cable connections utilizing either traditional 110 systems or tool-free modular connection hardware. The entire system easily exceeds the performance standards set forth by ISO/IEC for Category 6 cabling.

2) Siemon

Siemon products are often seen in structured cabling systems. Compared to AMP, Siemon is positioned as a premium brand with superior quality and advanced technical features. Naturally, its price is also significantly higher, making it rare to see its use in the DIY market. Additionally, Siemon provides a complete solution for structured cabling systems, including tools for assembling cables and wiring, which will be discussed later.

The Siemon SYSTEM 6 offers a frequency bandwidth exceeding 250 MHz while ensuring that all performance parameters within this range meet or surpass the requirements of the draft Category 6 standard. Siemon provides test reports and third-party certification (e.g., from DELTA and ETL) for all its Category 6 products (connection hardware and cables) and systems (basic links and channels).

3) Lucent

While Lucent is a well-known brand, it is rarely seen in the twisted-pair cable market, particularly among small- and medium-sized enterprises. However, this does not imply a lack of technical capability; on the contrary, Lucent frequently appears in high-end network setups. Backed by Bell Labs, Lucent Technologies has designed and developed an end-to-end "Category 6" cabling system known as SYSTIMAX GigaSPEED Solution, which innovates every component involved in connecting hosts and computers within networks, enhancing end-to-end system performance even further.

The GigaSPEED Solution is a cutting-edge product that meets or exceeds all indicators of the draft Category 6 standard. With 14 world patents, a typical GigaSPEED configuration includes horizontal UTP copper cables integrated with vertical backbone subsystems and campus-wide SYSTIMAX fiber optic connections. This solution delivers superior network performance while providing ample bandwidth for future network applications and technological advancements.

4) NORDX/CDT

NORDX/CDT's Gigabit Category 6 System 2400 uses IBDN PS5 enhanced connectors paired with IBDN Series 2400 unshielded cables to offer data transfer speeds of up to 2.4 Gbps. The cables provide high bandwidth capacity with extra margin to accommodate broader applications effectively. NORDX's new Category 6 product line-the IBDN System 4800LX-reaches data transfer speeds of up to 4.8 Gbps. It consists of new IBDN Series 4800LX cables, PS6 connectors, and PS6 standard cables capable of delivering bandwidths of up to 300 MHz. Compared with current draft proposals for Category 6 standards, the IBDN System 4800LX demonstrates significant improvements across all performance parameters.

5) IBM

IBM's ACS Silver Series products are compliant with ISO/IEC 11801 Category 6/Class E draft standards, EN 50173 Category E draft standards, and TIA/EIA-568 Category 6 draft standards. The ACS Silver Series supports bandwidths up to 200 MHz, offering better support for Gigabit Ethernet and other networks utilizing four-pair cables for data transmission.

The IBM ACS Silver Series is backward compatible with Category 5 or Enhanced Category 5 standards; both the Silver Series and Copper Series share compatible patch panels for easy upgrades while safeguarding investment value. Furthermore, IBM's ACS Silver Series represents a complete copper cabling solution operating at 100 ohms impedance; it can integrate seamlessly with IBM's ACS Crystal Series products for fiber optic connections between floors or buildings while enabling high-speed connections for slower horizontal systems through Silver Series products.

6) COBTEL

COBTEL is a globally recognized brand specializing in high-quality network cable reels and patch cords, renowned for its commitment to advanced technology and durable performance. With a strong presence in both domestic and international markets, COBTEL stands out for offering reliable products at competitive prices, making it a preferred choice for businesses of all sizes.

COBTEL's Category 6 and Category 6A network solutions are designed to meet and exceed international standards such as ISO/IEC 11801 and TIA/EIA-568. COBTEL's UTP and FTP cable reels feature oxygen-free copper cores for optimal conductivity, ensuring stable data transmission over long distances. These cables provide bandwidths of up to 250 MHz for Category 6 and up to 500 MHz for Category 6A, making them ideal for Gigabit Ethernet and high-speed data center applications.

COBTEL patch cords are manufactured with precision-molded RJ45 connectors and snag-free boots, ensuring durability and ease of use. They are available in various lengths and colors, catering to diverse networking needs. The cables undergo rigorous testing for performance and reliability, ensuring minimal signal attenuation and interference.

COBTEL also provides comprehensive structured cabling solutions, including tools for cable assembly, termination, and testing. With an emphasis on quality control, COBTEL offers third-party certifications for its cabling products, delivering peace of mind to its customers. Whether for enterprise-level installations or small-scale networking projects, COBTEL products represent a blend of quality, performance, and affordability, ensuring seamless connectivity for modern networks.

Previous:Cat6 Slim Cable