How To Choose A HDMI Cable:13 Key Points

Mar 05, 2025

Leave a message

In this article, we'll mainly focus on the 13 key points to consider on how to choose a HDMI cable.

1. How to choose a HDMI Cable Which Fits for yourself Really Matters

The widespread adoption of HDMI cables has made them a staple in many households. However, with the abundance of HDMI cable brands on the market, many users find themselves uncertain on how to choose a HDMI cable.

As a vital connection between playback devices and display devices, the quality of an HDMI cable directly affects the performance of televisions, projectors, or monitors.

A high-quality HDMI cable can create a "high-speed transmission channel" between input and display devices, ensuring interference-free data transmission and significantly enhancing the user's audio-visual experience. On the other hand, low-quality HDMI cables often lead to issues such as image ghosting, color distortion, water ripple effects, or an inability to automatically detect display settings. Inferior cables are frequently manufactured with only 13-pin or 15-pin cores and may lack essential shielding layers, which greatly compromise signal quality and can result in flickering, static-like snow, black screens, unsaturated colors, or poor audio quality. Additionally, poorly constructed cables may suffer from electrical issues such as poor contact or short circuits at their connectors.

For long-distance in-wall installations of HDMI cables in particular, substandard quality can severely impact signal transmission. Using a low-quality HDMI cable in these cases can lead to significant regret. That's why today we'll learn how to choose a HDMI cable.

2. Evaluating the Overall Capability of a HDMI cable Manufacturer.

From our earlier discussion on HDMI cables, it's clear that manufacturing them is a high-standard craft requiring advanced equipment and mastery of core technologies along with sophisticated processes to deliver top-quality products. Therefore, it's wise to check if the company invests in skilled personnel and advanced equipment. Only manufacturers with highly skilled professionals and cutting-edge technology can ensure reliable technical performance and extensive production expertise.

Reputable manufacturers of high-definition HDMI cables typically have independent production lines equipped with complete wire-drawing machinery, welding tools, testing instruments, and more. They also tend to establish dedicated product development teams capable of efficient R&D activities as well as semi-finished and finished product production capabilities.

HDMI Licensing Certification

Under international standards established by HDMI LA (Licensing Administrator), only companies recognized as members by the association are authorized to print the HDMI logo on their products and produce/sell HDMI cables. Certification signifies that a company's technology meets global standards set by the association. Therefore, when purchasing an HDMI cable, selecting one from a certified manufacturer is essential!.

3. Understanding Core Materials and Pin Counts in a HDMI Cable

Cables adhering to identical versions of the HDMI protocol can exhibit varying transmission performance depending on their core materials.

3.1 Understanding Core Material

Standard copper-core HDMI cables can efficiently synchronize audio and video signals while offering affordability and good value for money. However, they are prone to signal loss during long-distance transmissions due to attenuation-one reason why some users avoid regular copper-core options.

Common internal core materials for HDMI cables include:

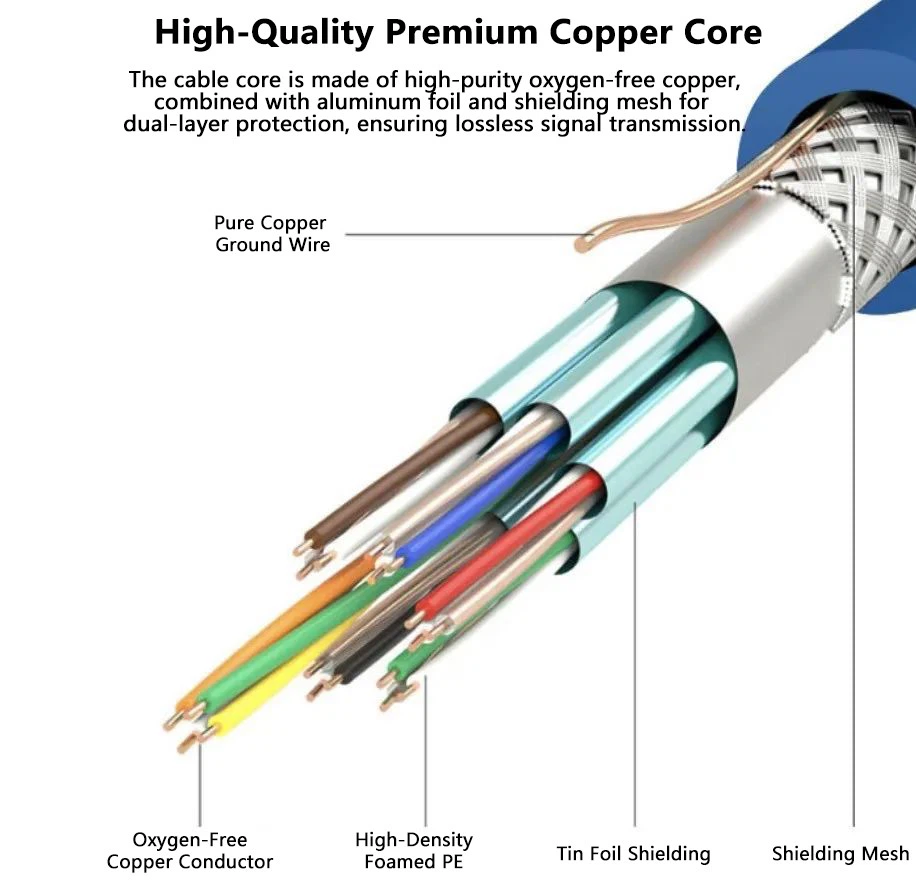

Oxygen-Free Copper (OFC): High-purity material used in standard-compliant products for superior performance.

Recycled Copper: Lower copper content leading to reduced efficiency.

Copper-Clad Steel (CCS): A cheaper alternative with compromised conductivity compared to pure copper cores.

Copper-Clad Iron (CCI): An even less efficient option commonly found in non-compliant products.

Non-compliant products often utilize cheaper alternatives like CCS or CCI cores whose performance falls far short of OFC cores-sometimes even failing to meet minimum requirements for modern high-definition displays.

For better oxidation resistance and conductivity than standard copper cores offer, silver-plated oxygen-free copper or tin-plated oxygen-free copper cores are excellent choices. These options effectively shield against interference while improving signal transmission performance and have become popular in mainstream markets.

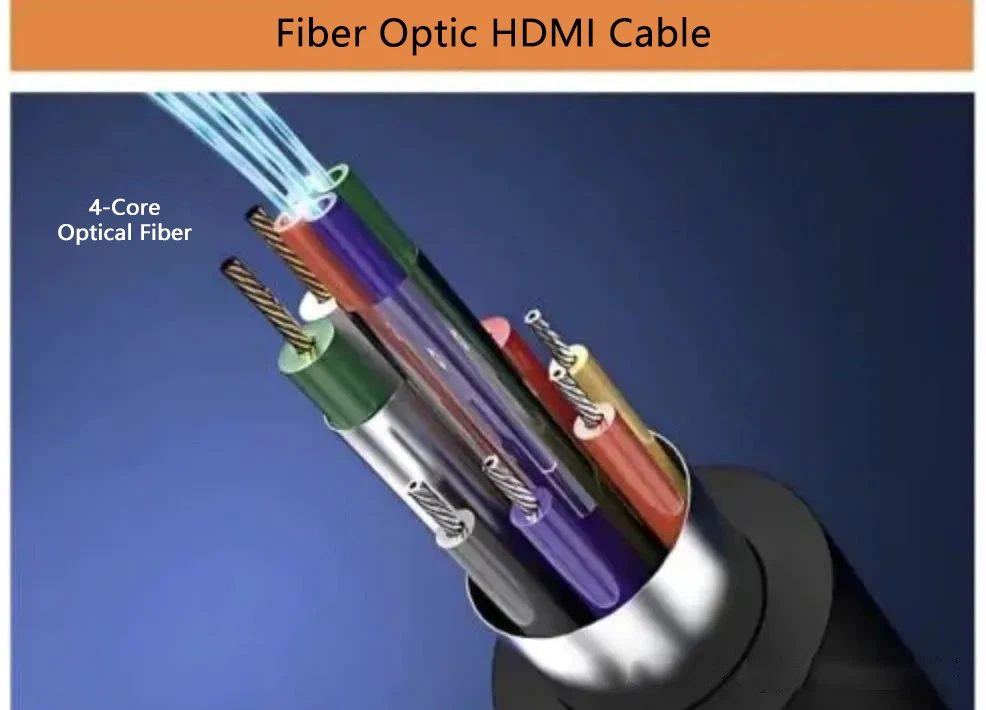

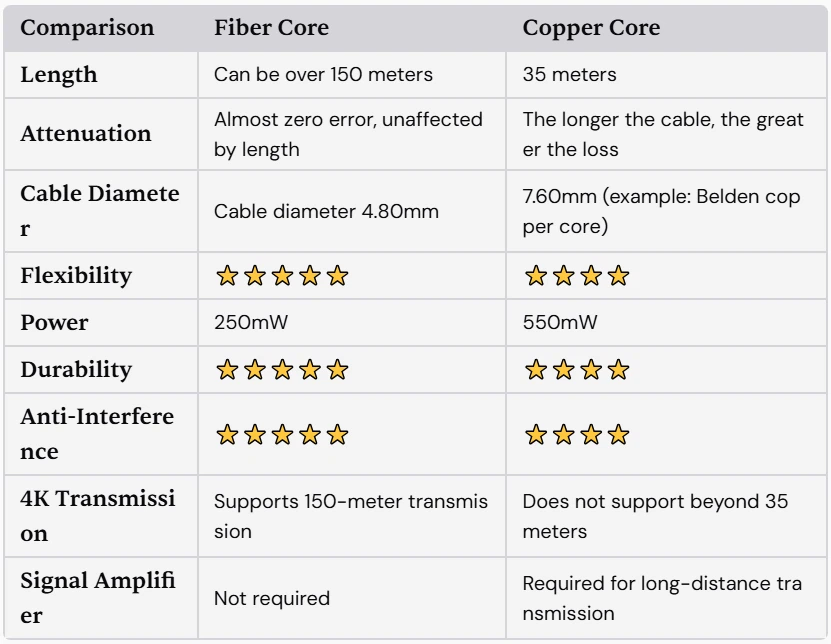

For optimal performance over long distances though, fiber-optic HDMI cables stand out due to their hybrid design combining optical fibers with copper wires internally. Data travels through light within fiber-optic cores rather than electrical current-eliminating electromagnetic interference issues while resolving signal loss challenges associated with traditional copper-core setups. However, fiber-optic HDMI cables are significantly more expensive-often several times pricier than conventional ones.

3.2 Understanding Pin Count in a HDMI Cable.

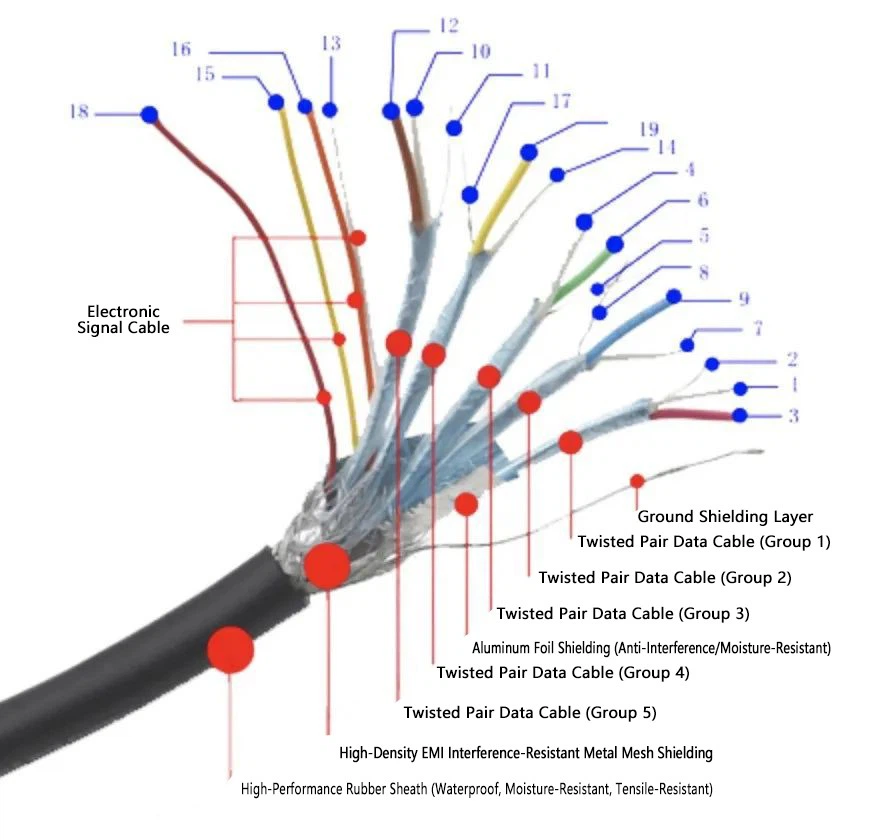

High-performance standard-compliant HDMI cables feature full-spec 19+1 pins for a total of 20 conductors meeting association specifications. Non-standard versions often cut corners by reducing ground wires-typically configured as 13+1 or 15+1 pins instead.

Most non-standard cables on today's market lack four shielding wires along with two functional lines compared to full-spec models-leading to noticeably reduced signal transmission performance.

A HDMI cable is internally structured with 19 individual functional cores-including four pairs (eight wires total) dedicated for TMDS data differential signaling plus additional conductors assigned for clock signals/CEC control signals/power supplies/grounding-HDMI cables ensure stable high-definition audio-video transmissions through precise designs.

Understanding these internal constructions and functions helps consumers choose models that maximize their multimedia experience!

4. Inspecting the Shielding Layer and Materials of a HDMI Cable.

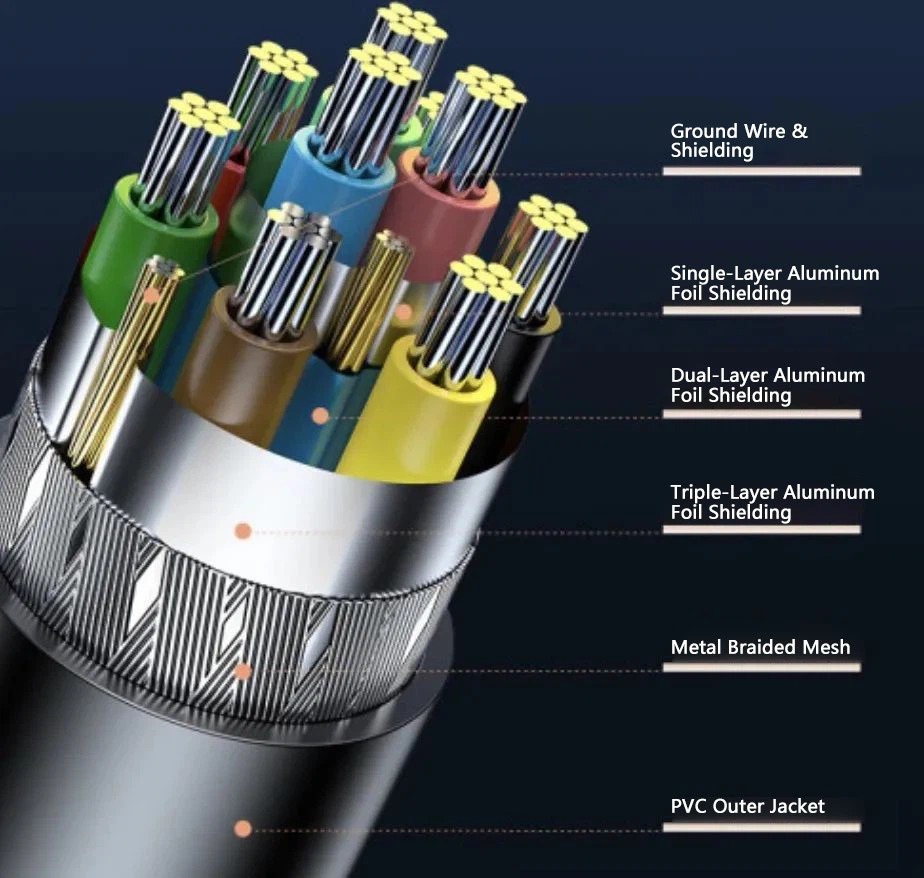

The transmission performance of HDMI cables is closely related to their shielding layer. The purpose of the shielding layer is to prevent signal interference between the internal and external environments of the cable, thereby ensuring clear audio and video transmission. The effectiveness of the shielding layer depends on the coverage density of its shielding material-the higher the density, the better the shielding effect. Generally, HDMI cables feature a metal braided layer with an 85% coverage rate and an aluminum foil layer with 100% coverage. For standard-grade HDMI cables, in addition to a PVC outer jacket, the internal core typically includes 2–3 shielding layers such as aluminum foil, metal braid, and a ground wire made of pure copper or tinned copper. High-quality HDMI cables may incorporate additional shielding layers and tensile reinforcement materials to enhance durability and reduce wear caused by bending, stretching, or compression.

Regarding shielding layers:

Having more layers does not necessarily result in better shielding performance; low-quality materials with poor shielding efficiency render extra layers ineffective.

Low-cost, inferior-quality HDMI cables often use bare copper, copper-clad aluminum (CCA), or aluminum wires for shielding layers, which are less effective than tinned copper wires.

Nylon mesh braiding is mainly for aesthetic purposes and does not contribute to signal shielding.

HDMI cables with magnetic rings are not inherently superior; magnetic rings function to filter noise-such as electromagnetic interference from nearby devices-and reduce signal interference but are generally only needed when the cable's intrinsic anti-interference capability is weak.

5. Inspecting the Outer Jacket of a HDMI Cable.

A high-quality HDMI outer jacket is very robust; it's impossible to tear it by hand-you'll need scissors or pliers. In contrast, PVC jackets made from recycled materials can be easily torn by hand with minimal force. Beneath the first PVC layer lies a dense and durable aluminum-magnesium shielding layer that also requires tools to cut through; beneath this is typically an aluminum foil layer as the third shield.

High-quality HDMI cables commonly use two types of outer jacket materials: PVC and nylon braiding.

PVC Outer Jacket: The Key to Wear Resistance and Durability

PVC outer jackets are made from amorphous materials that exhibit excellent resistance to oxidation, strong acids, and reduction reactions. HDMI cables with PVC jackets are resistant to wear, stretching, and aging, offering excellent strength and stability. Whether for daily use or extended connections, PVC jackets provide reliable protection.

PVC outer jackets are made from amorphous materials that exhibit excellent resistance to oxidation, strong acids, and reduction reactions. HDMI cables with PVC jackets are resistant to wear, stretching, and aging, offering excellent strength and stability. Whether for daily use or extended connections, PVC jackets provide reliable protection.

Nylon Braided Outer Jacket: A Choice for Enhanced Toughness and Tensile Strength

Premium HDMI cables often feature nylon braided outer jackets that protect internal components while improving overall performance. Nylon-braided cables are less prone to tangling, have a denser texture, superior abrasion resistance, and remain durable without fraying even after extended use.

Premium HDMI cables often feature nylon braided outer jackets that protect internal components while improving overall performance. Nylon-braided cables are less prone to tangling, have a denser texture, superior abrasion resistance, and remain durable without fraying even after extended use.

6. Inspecting Wire Gauge Standards of a HDMI Cable Cores

When purchasing HDMI cables, you might encounter references to wire gauges such as 26AWG or 24AWG on product descriptions-or even printed directly on cable jackets-but do you know what AWG stands for? (American Wire Gauge). Not just limited to HDMI cables, AWG parameters can also be found in other video or network cabling systems.

AWG stands for "American Wire Gauge," a standard established in the U.S., which specifies conductor grades and diameters within HDMI cable cores. Also known as Brown & Sharpe gauge standards, AWG numbers (e.g., 24AWG or 26AWG) indicate how many drawing stages were required before achieving the final diameter-the larger the number, the thinner the conductor diameter.

This inverse relationship means thicker wires have better physical strength and lower electrical resistance-basic principles you might recall from middle school physics!

Thicker cables can carry higher currents with reduced resistance but require more copper during manufacturing, resulting in heavier cables that are harder to install and more expensive.

The design challenge is balancing thinner conductors (to lower costs and simplify installation) with maintaining sufficient capacity at required voltage and frequency levels.

Wire core thickness significantly impacts transmission performance in HDMI cables. Current wire gauge standards for HDMI cores range from 24–30AWG; smaller numbers indicate thicker cores with larger cross-sectional areas that provide lower resistance, less signal loss, and longer transmission distances.

While smaller AWG values yield superior performance, overly thick cables may complicate installation.

For transmission distances between 1–10 meters, 28–30AWG HDMI cables are sufficient because they are lightweight and easier to install. However, for longer distances requiring more stable signal transmission, consider using 24–26AWG cables or those equipped with signal amplification chips.

7. Consider the HDMI Interface Version of a hDMI Cable.

When choosing an HDMI cable, consider the HDMI interface version. On many display devices, you might see labels like HDMI 2.0 or HDMI 2.1 on their interfaces. Technically, HDMI cables don't have versions assigned to them; these labels actually refer to the classification of the device's HDMI interface version. In our previous articles, we discussed all HDMI interface versions from HDMI 1.1 to HDMI 2.1 and highlighted the distinctions between each version.

Currently, the primary HDMI interface versions available on the market are 1.4, 2.0, and 2.1-each supporting varying levels of transmission protocols and video resolutions. Higher versions allow for better audio-visual performance and are backward compatible with lower versions.

For example, if you use an HDMI cable labeled as version 1.4 with a TV or display device that supports version 2.0 or 2.1, the transmitted video signal will only adhere to the bandwidth and resolution supported by HDMI 1.4-meaning it won't deliver true 4K resolution at 2160P and 60 frames per second for ultra-high-definition video.

In terms of bandwidth and video resolution:

HDMI 1.4: Supports up to 4K at 30Hz with a bandwidth of 10.2Gbps;

HDMI 2.0: Supports up to 4K at 60Hz, along with features like 3D video and static HDR, with a bandwidth of 18Gbps;

HDMI 2.1: The highest specification version currently available, offers a bandwidth of up to 48Gbps, supports resolutions up to 8K (four times the bandwidth required for ultra-HD at a resolution of 4K), allows output of up to 4K resolution at a refresh rate of 120Hz, and supports advanced features such as dynamic/static HDR and various picture enhancements for smoother gaming experiences without ghosting or frame drops.

Higher-version cables naturally come at a higher cost for the same length due to their advanced capabilities.

Make sure you understand these differences among HDMI versions before selecting one based on your specific setup and device requirements.

8. Check the Type of HDMI Interface of a hDMI cable.

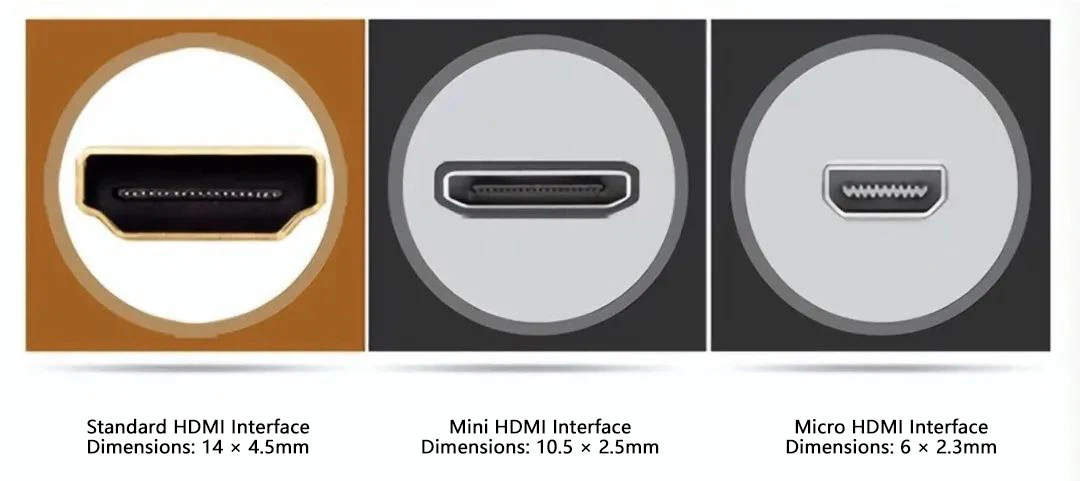

There are five types of HDMI interfaces: Type A (Standard), Type B (Dual-Link), Type C (Mini-HDMI), Type D (Micro-HDMI), and Type E (Automotive). Before purchasing an HDMI cable, confirm the type of HDMI interface on your display device to ensure compatibility.

The most common types are:

Standard HDMI Interface (Type A): Approximately 15mm wide;

Mini-HDMI Interface (Type C): Approximately 10.5mm wide;

Micro-HDMI Interface (Type D): Approximately 6mm wide.

Each type has a distinct size and physical design, making them non-interchangeable by nature-so be sure to verify your device's specific interface type before buying an HDMI cable.

9. Inspect The HDMI Connector Quality and Pin Construction of a hDMI Cable.

For cables with gold-plated connectors, beyond their sleek appearance, gold plating provides benefits such as better corrosion resistance, superior conductivity, ease of soldering, high-temperature tolerance, and enhanced wear resistance-making gold-plated connectors generally superior to non-gold-plated ones on the market today (most feature high-brightness 24K gold plating). However, while gold plating enhances durability externally, what ultimately matters is the performance of the internal pins inside the connector that interact directly with your device's interface.

These pins are typically made from tin-bronze alloy due to its high elasticity, excellent wear resistance, and corrosion resistance properties. High-quality pins often feature three layers: nickel plating over tin-bronze followed by gold plating for enhanced durability and performance.

As for connector housings: while plastic is commonly used in standard cables, higher-end options utilize aluminum or zinc alloy casings-which may not directly affect signal quality but offer improved aesthetics and greater durability under frequent use compared to plastic alternatives.

10. Consider Whether To Choose a Fiber Optic HDMI Cable.

Fiber optic HDMI cables are becoming increasingly common among manufacturers as they address several shortcomings associated with traditional copper-based long-distance cables: they support significantly longer transmission distances without noticeable signal degradation; they can be made much thinner for easier installation; they provide more stable performance compared to fragile copper-based cables.

While fiber optic HDMI cables are highly popular for these reasons, they also come with drawbacks-primarily their cost due to requiring two optical-electrical conversion chips in each cable: one chip converts electrical signals into optical signals at one end while another converts them back into electrical signals at the other end. These chips make fiber optic cables more expensive than traditional options-often costing several hundred dollars per meter-but their average unit cost decreases over longer distances.

One critical aspect when using fiber optic cables is their directional nature because of these chips (with designated input/output ends). Make sure you install them in the correct direction during setup.

As for deciding when fiber optic cables are necessary: copper-based options suffice for standard HD signal transmission over shorter distances (up to approximately five meters). However, when transmitting ultra-HD content like 4K@60Hz over longer distances exceeding ten meters, fiber optic cables are recommended for maintaining superior stability in delivering high-resolution signals across extended lengths effortlessly.

11. Check Whether a hDMI Cable's Features Include ARC and CEC

ARC and CEC are critical features in HDMI cables, but not all HDMI cables support them. When purchasing, make sure to confirm this clearly. Some HDMI ports may have labels indicating whether they support ARC functionality.

ARC, or Audio Return Channel, is a feature introduced by the HDMI Forum in 2009 alongside the release of HDMI version 1.4. Its main purpose is to transmit audio signals and establish audio interconnectivity between a TV and a sound system. Specifically, if an HDMI port supports ARC functionality, the TV can transmit audio signals through the HDMI cable to an amplifier or other audio device with HDMI ARC capabilities, allowing the sound system to take over from the TV's built-in speakers.

In 2017, with the introduction of HDMI version 2.1, the HDMI Association added eARC (Enhanced Audio Return Channel), an upgraded version of ARC.

The CEC (Consumer Electronics Control) feature in HDMI enables users to control other CEC-enabled devices connected via HDMI. For example, when a user inserts a disc into a Blu-ray player, the TV powers on automatically due to receiving a CEC signal, and its video channel switches to the input connected to the player. Similarly, when turning off the TV, a CEC signal notifies connected devices to enter standby mode as well. This allows users to control all HDMI-connected devices with a single remote, eliminating the inconvenience of juggling multiple remotes for different devices. The CEC function has been supported since HDMI version 1.3. If there is no clear indication of whether ARC and CEC are supported, we need to ensure that the version meets or exceeds the required standards for these features and verify their support with the manufacturer.

12. Test a HDMI Cable's Performance

Ideally, eye diagram tests and DC resistance measurements should be conducted to test an HDMI cable's performance; however, these require expensive oscilloscopes and must be performed by professional institutions equipped for such testing.

For ordinary users, there is a simpler way: verifying whether a newly acquired HDMI cable can operate correctly under its claimed maximum specifications.

So how do you do this? You need a source device capable of supporting 48Gbps bandwidth-for example, using a Sony PS5's HDMI 2.1 interface (which supports up to 32Gbps) or an Xbox Series X/S (which supports up to 40Gbps). Alternatively, you can use NVIDIA GPU graphics cards with an HDMI 2.1 interface capable of outputting at 48Gbps as your testing source.

Connect the tested HDMI cable from such an output source to a television equipped with an HDMI 2.1 interface that supports 48Gbps bandwidth. Configure settings for 4K resolution at a 120Hz frame rate with RGB color depth at 12 bits per channel (12-bit). If there are no issues such as black screens, flickering images, or mosaic artifacts during operation under these conditions, then your testing is complete.

13. Check Whether a hDMI cable Pass The Verification Of The HDMI Ultra High-Speed Certification Label

As the HDMI market grows more diverse, consumers now face countless options when choosing cables-but this abundance also leads to confusion about product specifications or whether cables meet official standards. To address these concerns:

HDMI has introduced online verification methods that allow consumers to check products before purchasing them. Look for verification QR code provided by authorized adopters and retailers on shopping websites; scaning on these QR codes takes users directly to official pages hosted by hdmi.org. Here, they can check essential details such as adopter status, product certification status (e.g., brand name and model), and cable length certification-ensuring they purchase genuine high-performance cables that meet their needs without worrying about authenticity.

To obtain formal authorization for products:

In summary:

It's recommended that consumers choose only officially certified Ultra High-Speed HDMI® cables bearing proper certification logos on their packaging. This helps avoid confusion or potential issues with unverified alternatives while ensuring compliance with industry standards for optimal performance and reliability.

It's recommended that consumers choose only officially certified Ultra High-Speed HDMI® cables bearing proper certification logos on their packaging. This helps avoid confusion or potential issues with unverified alternatives while ensuring compliance with industry standards for optimal performance and reliability.