What Is Profinet Cable?

Aug 11, 2023

Leave a message

1. What drives the evolution of industrial field buses toward profinet Cables?

Over the past few decades, Ethernet technology has been continuously changing the rules of the game in various industries, from early local area networks (LANs) to later broadband networks, and now to the present internet. Currently, the key components of Ethernet technology are being used in industrial control field buses, driving the evolution and advancement of the entire manufacturing industry ecosystem.

In fact, for many years, traditional Ethernet technology and TCP/IP protocol have already been widely applied in network information systems of enterprises and workshops, as well as in production and operation management systems in the manufacturing industry. However, they have been rarely used for the interaction and communication of control data and information within actual machine equipment and production lines.

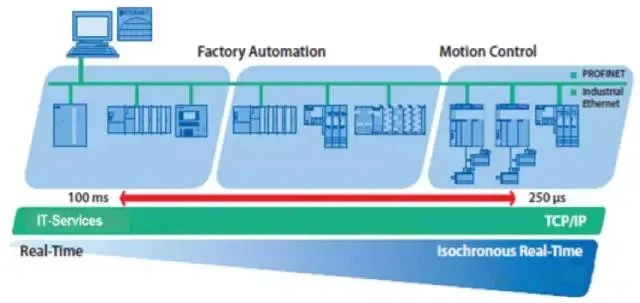

Communication between machine controllers themselves (such as PLCs, IPCs, etc.) and their actuators (such as drives, motors, etc.) and sensors always requires the use of deterministic field control buses. However, using the traditional TCP/IP protocol cannot achieve and satisfy the real-time deterministic requirements for communication from machine control to sensors and actuators, making it unsuitable as a control-layer bus for industrial equipment.

However, in the equipment manufacturing industry, machine manufacturers (such as those producing CNC machines, semiconductor equipment, etc.) have recognized the value of reusing hardware components configured on TCP/IP networks. Due to the explosive growth of the internet, a widely accepted technical standard has been created for Ethernet communication components (such as communication cards, cables, connectors, etc.), significantly reducing their costs. These network interface cards (NICs) and TCP cables cost only a fraction of traditional industrial fieldbus cables and data acquisition cards (DAQ cards). Therefore, compared to the traditional configuration of specialized industrial field buses, reusing such Ethernet hardware can help companies save a significant amount of economic costs.

The economic benefits of adopting Ethernet as a field bus are undeniable, as Ethernet components can significantly reduce system costs while maintaining excellent versatility.

For example, if a proprietary fieldbus is adopted, robot manufacturers must purchase a complete set of control system components from a single supplier: dedicated I/O modules, servo drives, motors, expensive cables, connectors, and so on.

By using Ethernet-based standard communication protocols, I/O modules can be replaced with universal Ethernet interfaces, specialized bus communication cables can be substituted with ordinary CAT5 (Category 5) twisted-pair cables, and if the network standards can support multiple suppliers, the cost of servo drive systems will also be significantly reduced.

At the same time, connecting equipment system components using Ethernet will become simpler. For instance, compared to using complex specialized bus communication cables on equipment controllers and electrical components, using common CAT5 cables similar to those used for home/office computers when connecting to the internet will make equipment management and maintenance easier. These benefits are just a part of the economic advantages brought about by Ethernet technology.

The industry quickly realized that despite TCP/UDP/IP protocols not being able to provide the real-time deterministic response required by industrial control systems, the ubiquitous and low-cost Ethernet hardware, including network interface cards (NICs) and CAT5 Ethernet cables, can be applied in industrial equipment systems to provide the required real-time response for control applications.

What we need is a new real-time communication protocol that can utilize the Ethernet's hardware physical layer and, at the same time, ensure real-time determinism in the connection and communication between device controllers and all sensors and actuators within the devices.

Since the beginning of this century, major well-known industrial automation manufacturers have introduced at least five different real-time industrial Ethernet communication protocols, such as EtherNet/IP, EtherCAT, PowerLink, ProfiNet, and SERCOS III, among others. They are all promoted as "standards," claiming to enable the reuse of Ethernet protocols or hardware and promising to lower the construction costs of real-time control systems.

The existence of multiple potential "standard" Ethernet protocols might be due to a significant reason: each manufacturer has distinct technical methods to achieve the reuse of Ethernet hardware components (such as network interface cards and CAT5 cables), significantly reducing equipment costs while enhancing machine performance, and allowing data transmission and interaction to support real-time deterministic applications.

The simultaneous presence of multiple potential "standard" Ethernet protocols might have another reason as well. Leading industrial automation manufacturers are attempting to leverage Ethernet technology to save the overall costs of their system solutions. By extending their product "standards" to Ethernet, customers can indeed gain advantages and value from Ethernet technology. However, in the long run, they remain tightly locked within the manufacturers' proprietary networks.

Additionally, the emergence of new protocols can indeed help users leverage Ethernet technology to surpass existing device performance and costs. At the same time, compared to any other traditional industrial Fieldbus, machine manufacturers adopting the right real-time Ethernet fieldbus standard will also gain a very noticeable competitive advantage in terms of cost-effectiveness.

Meanwhile, for machine manufacturers and equipment users, these factors might no longer be as crucial, as after years of promotion and popularization of industrial Ethernet technology and products, the challenges faced by users are no longer between choosing traditional industrial control buses and industrial Ethernet, but rather dealing with the fierce competition and the different values and advantages demonstrated by various industrial Ethernet protocol "standards" in the complex and crowded market. It is difficult to determine which "standard" is the right choice. Adopting an incorrect (inappropriate) protocol as a standard could lead to unnecessary cost consumption and sacrifice competitive advantages due to reduced performance.

In discussions about various aspects of industrial real-time Ethernet, some seemingly simple facts are often overlooked. The selection of network protocol standards is not only about the technical specifications and attributes, such as performance and transmission rate, but also encompasses soft indicators and parameters related to application experiences, such as usability, openness, independence, risk avoidance, consistency, interoperability, long-term availability, and system distribution characteristics. When combined, these factors will determine whether a protocol and "standard" can be accepted by users or become popular in the market.

2. Characteristics of Profinet Cables (industrial Ethernet cables).

In the Ethernet connections within the industrial sector, there are various types of cables designed for different usage environments, such as shielded cables or unshielded cables. These cables can also vary based on the cable material. Below, I will provide a brief overview of commonly used industrial-grade Category 5e (Cat 5e) cables according to the application environments they are intended to address:

2.1 Ultra-Strong Shielding Protection

Cat 5e, Ultra-Flexible PUR Jacket, Double Shielding, 4 Pairs of 26 AWG Twisted Pair Conductors

To combat interference sources in industrial settings, this cable employs an aluminum foil/braid double shielding structure, along with a PUR jacket that is resistant to ultraviolet (UV) exposure and oil-based lubricants. It is particularly suitable for industrial Ethernet applications with strong electromagnetic interference (EMI) and radio frequency interference (RFI).

2.2 Moisture and UV Resistance

IP6 outdoor-rated waterproof cable with UV-resistant jacket, Cat 5e cable

This series of cables feature a PE or TPE jacket with moisture and UV-resistant properties, making them suitable for outdoor installations to prevent damage caused by water and sunlight. Some models even allow direct burial, and certain types are designed for use in cellular base station cabling. Moreover, most models use solid conductors that are easy to terminate with IDC connectors and modular connectors, making them well-suited for Power over Ethernet (PoE) applications.

2.3 High Flexibility, Corrosion Resistance, and Oil Resistance

Cat 5e SF/UTP cable, highly flexible CMX flame-retardant TPE jacket, 4 pairs of 26 AWG stranded conductors

This unique series of highly flexible shielded Cat 5e cables is designed for challenging environments where regular cables may not be sufficient. It can withstand harsh conditions and does not break down when exposed to oil-based lubricants, making it ideal for robot control systems in factory workshops. These cables have also been tested to endure 10 million bending cycles.

2.4 Industrial-Grade Shielded Cat 5e Cable and Unshielded Cat 5e Cable

→ Of course, in industrial applications, one might not necessarily encounter extremely harsh conditions. When selecting cables, the choice between shielded and unshielded types is generally considered first:

2.4.1 Industrial-Grade Shielded Cat 5e Cable

Cat 5e, PVC, Foil Shielding, 4 Pairs of Twisted Pair Conductors, 26 AWG

Configured with an aluminum foil shielding layer and a grounding wire, this shielded twisted pair cable effectively resists electromagnetic interference (EMI) and radio frequency interference (RFI) encountered in application environments. For stronger interference, models with both aluminum foil and braided shielding can be chosen. The flame-retardant series features 24 AWG solid conductors.

2.4.2 Industrial-Grade Unshielded Cat 5e Cable

Cat 5e UTP cable, riser-rated jacket, 4 pairs of 24 AWG solid conductors

Due to the advantages of cost savings and easy assembly, unshielded twisted pair cables are the most widely adopted network cables.

Previous:Network Cable Explained