Network Cable Explained

Leave a message

Network cable explained: In low-voltage monitoring systems, network cables are essential materials for connecting local area networks. When setting up a monitoring low-voltage system, people often focus on selecting important equipment such as cameras, switches, DVRs, decoders, and streaming media servers. However, they may not be very selective when it comes to choosing network cables. This can lead to many problems after project acceptance, and many of these issues are related to the cable link. Today, let's discuss and explain the basics of network cables!

1. Cable Classification

Network cables are the most commonly used transmission medium in structured cabling systems. A network cable consists of 4 pairs of wires with 8 cores in total, each core being color-coded for data transmission. Its characteristics mainly include easy implementation, affordability, and suitability for various scenarios in structured cabling systems.

1.1 Classified based on performance

According to the ISO/IEC 11801 standard, network cables can be classified into Cat5 cable, Cat6 cable, Cat6A cable, and Cat7 cable.

Cable Specifications

Cat5 Cable: It has been replaced by Category 6 cables. It is used for data transmission with a maximum speed of 100Mbps and is mainly used in 10BASE-T and 100BASE-T local area networks(LANs).

Cat6 Cable: Category 6 cables have improved crosstalk and return loss performance compared to Category 5 cables. Their transmission performance is much higher, making them suitable for Gigabit Ethernet applications.

Cat6A Cable: This is an upgraded version of Category 6 cables and is primarily used for 10 Gigabit Ethernet. It has a transmission frequency of 500MHz and a maximum transmission speed of 10Gbps, with significant improvements in external crosstalk.

Cat7 Cable: Category 7 cables are shielded twisted-pair cables with a transmission frequency of at least 600MHz and a transmission speed of 10Gbps. They are used for 10 Gigabit Ethernet.

It's important to pay attention to cable selection and ensure that the right type of cable is chosen for the specific requirements of the monitoring system to ensure optimal performance and reliability.

1.2 Classified by Material

Network cables can be classified by material, including oxygen-free copper, aluminum wire, copper-clad aluminum, and copper-clad steel.

Oxygen-Free Copper Network Cable: Oxygen-free copper is the best and highest-quality cable material. It is suitable for Power over Ethernet (POE) supply due to its low resistance, reducing power loss during transmission. For POE supply in monitoring systems, oxygen-free copper cables are the preferred choice.

Material: Oxygen-free copper offers optimal performance.

Aluminum Wire: Aluminum wire quality is inferior to oxygen-free copper, but it is suitable for short-distance transmission without major issues. It can be used for connecting devices in homes or small offices. It has higher resistance compared to oxygen-free copper and is suitable for short-distance POE supply in monitoring systems.

Material: Aluminum wire performance is second to oxygen-free copper.

Copper-Clad Aluminum: This type of cable has a layer of copper-plated over aluminum wire. The skin effect improves the conductivity of the aluminum wire, although it has higher resistance. It is suitable for short-distance POE supply in low-voltage monitoring systems.

Performance: Copper-clad aluminum cable has inferior performance.

Copper-Clad Steel: This cable has a layer of copper-plated over steel wire. The skin effect enhances the conductivity of the steel wire, but it has higher resistance. It is not suitable for POE supply in monitoring systems.

Performance: Copper-clad steel cable has inferior performance.

1.3 Classified by Usage Environment

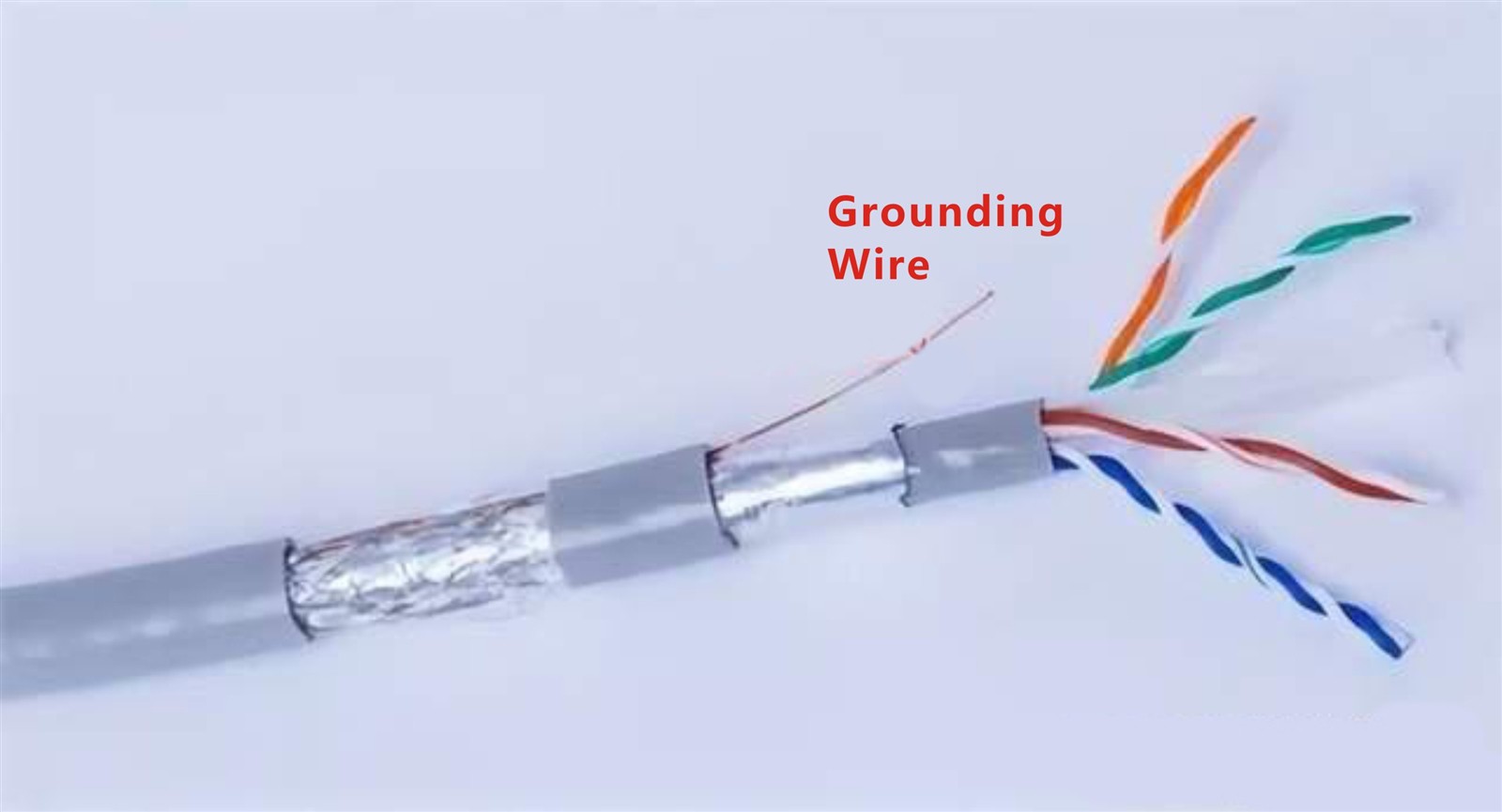

In environments with complex electromagnetic interference, it is recommended to use shielded network cables. Shielded cables have internal structures that effectively reduce external interference, ensuring normal signal transmission. Additionally, the aluminum foil material in shielded cables can prevent electromagnetic leakage from the cable itself, preventing interference signals from affecting other cables' operation and protecting against eavesdropping. Shielded cables can be categorized as single-shielded and double-shielded.

Single-Shielded Network Cable:

A single-shielded network cable has a layer of aluminum foil inside to reduce electromagnetic radiation.

Single-Shielded Network Cable:

Double-Shielded Network Cable:

A double-shielded network cable wraps aluminum foil around the twisted pairs and adds a layer of metal braiding. It is suitable for high-speed networks and high-security signal transmission, effectively reducing electromagnetic interference.

Cat7 double-shielded cable

Implementation:

Implementing shielded network cables requires the entire system to be made of shielded materials, including shielded cables, shielded connectors, and shielded devices. Shielded RJ45 connectors with grounding pins are used. Proper grounding is essential for the effective shielding of external signals. Shielded network cables have strict requirements for structured cabling, necessitating all system components to have shielding capabilities and proper grounding for optimal performance. Otherwise, the shielding effect might be compromised.

Grounding Wire/Earth Wire:

Shielded RJ45 Connector:

2. Methods for Identifying Network Cable Performance

2.1 Cable Sheath

Currently, the specifications of network cables are indicated on the cable sheath. For instance, CAT5 denotes Category 5 cable, suitable for 100 Mbps Ethernet data transmission. CAT5E is for Category 5 Enhanced, an entry-level product for Gigabit Ethernet. CAT6 is for Category 6, used to set up Gigabit Ethernet, and is the mainstream network cable today.

Cable Specifications Label Marking

2.2 Flame Test

Use a lighter to test the flame retardancy. Authentic network cables must have flame resistance. When the flame is applied to the outer sheath, it will gradually melt and deform. However, the outer sheath should not catch fire on its own. If the outer sheath burns easily, these cables do not meet safety standards and are not suitable for large-scale structured cabling systems.

2.3 Magnet Test

Using a magnet can identify cables with iron cores. If a network cable can be attracted by a magnet, it indicates that the cable has an iron core. Iron core cables have higher resistance, which significantly impacts transmission speed and distance, making them unsuitable for use.

2.4 Cable Bending Test

Authentic network cables made of oxygen-free copper are of pure material, soft texture, and flexibility. They won't break easily when bent.

2.5 Twisting Direction of the Cable

The twisting direction of the cable should be counterclockwise, not clockwise. A clockwise twist can affect transmission quantity and distance.

2.6 Length

The standard length of authentic network cables is 305 meters. Fake cables might fall short in length.

3. Network Cable Assembly With RJ45 Connectors

3.1 There are two types of connections for network cable and rj45 connectors: straight-through and crossover. For straight-through, both ends follow either the T568A or T568B standard. For crossover, one end follows T568A, and the other end follows T568B. Previously, crossover cables were required for connecting similar devices like routers to routers or switches to switches. However, modern network devices support automatic line sequence conversion, allowing straight-through cables to be used for similar device connections.

T568A/T568B Wiring standard

3.2 RJ45 Connector Line Sequences

T568A Wiring Sequence: ① White-Green ② Green ③ White-Orange ④ Blue ⑤ White-Blue ⑥ Orange ⑦ White-Brown ⑧ Brown

T568B Wiring Sequence: ① White-Orange ② Orange ③ White-Green ④ Blue ⑤ White-Blue ⑥ Green ⑦ White-Brown ⑧ Brown

4. Network Cable Testing

After connecting the RJ45 connector, the network cable needs to be tested using a cable tester or other appropriate equipment like Fluke devices for more demanding projects.

4.1 Cable Tester

A cable tester typically has 8 indicator lights. When an unshielded network cable is inserted into the tester interface, lights corresponding to connections 1-8 will sequentially light up. For shielded cables, in addition to connections 1-8, the shield indicator light (G light) will also illuminate.

Network Cable Tester

4.2 Fluke Testing

For advanced structured cabling systems, conventional cable testers or equipment like Fluke may be inadequate for testing attenuation and other parameters. Fluke devices are used to test the cabling system's cables and ensure compliance with acceptance standards.

Fluker Tester

5. Extending Network Cables

In a structured cabling system, when cable estimates fall short and reserved cables are too short, extension methods like RJ45 couplers, keystone jacks, or soldering can be used.

5.1 Inline Couplers

Couplers are commonly used for extending network cable connections. Separate the 8-core wires of the network cable and insert them into the coupler. You need two couplers for each end. Then, insert the wires of the same color into the corresponding slots of the coupler. Finally, use needle-nose pliers to press down on the top of the coupler's slot to secure and tighten the connection.

Terminal Block

5.2 Keystone Jacks

Network cable keystone jacks come in indoor and outdoor variants. Indoor keystone jacks can have RJ45 connectors attached at both ends and then the keystone jack is connected to the cable. This connection is very convenient. Outdoor keystone jacks are similar to indoor ones, but they have waterproofing capabilities. They are used for connections like CCTV camera tail lines and network cables, ensuring reliable outdoor use after being securely tightened.

Indoor Keystone Jack

Indoor Feed-through Keystone Module

Outdoor Feed-through Keystone Module

5.3 Soldering

You can strip the network cable's wire cores, exposing the copper wires. Slide heat-shrink tubing over the exposed wires and solder them using a soldering iron. This method requires a higher level of craftsmanship.

Cable Soldering Process

6. Conclusion

When working on projects involving low-voltage surveillance systems, network cables are essential transmission media for connecting devices and are critical factors in the stability of the entire low-voltage system. When using network cables, it's important to understand their categories, authenticity verification, assembly, testing, and cable extension methods. These fundamental yet practical pieces of knowledge need to be mastered as they play a crucial role in practice.