how-to-solve-the-breaking-of-the-optical-fiber

Leave a message

What should we do if my fiber optic is broken?

-There are 2 solutions to the problem.

What should we do if the fiber optic cables were broken in the operation? This kind of situation frequently occurs in the operations of low-voltage projects.

If the fiber optic cable is broken, the optical fiber fusion splicer needs to be used in order to connect the two fiber optic cables together. Since the optical fiber is made of quartz, it can not be knotted like an electrical wire, we must use professional equipment worthy of thousands of dollars to finish the thermal splicing, however, most of the time, we don't have a fiber optic fusion machine around.

1. An optical fiber's cold splicing method

If there are no other better ways, then you can choose the cold splicing method.

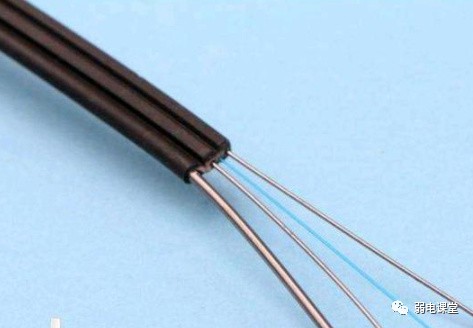

Optical fiber is generally made of three wires side by side, but the real fiber which functions is the one sandwiched in the middle, the main role of the two side wires is to protect the middle one, because the fiber is very brittle and easy to break, so the "bodyguards" are arranged for protection.

Sometimes, there may be two or three fibers in the middle, then we only need to use the blue one, and the other extra fibers can be broken without any effects on the function.

2 The optical fiber's cold splicing steps

Now the FTTH (Fiber to the home) users usually use the Leather line cable, both of the ends are cold splicers, The so-called cold splicing, that is, to strip and cut the optical fiber, aligned with the cold splicer, and then being fixed. Cold splice is more convenient, no need to use a fiber fusion splicer machine.

FTTH(Fiber to the home) cold splicing mainly includes stripping, cleaning, cutting, cold splicing, and testing, five major steps in total.

2.1, Stripping

2.1.1 Unscrew the tailpipe of the splicer, and then insert the optical fiber into the tailpipe.

2.1.2 Use the fiber stripper to strip the PVC layer, and cut the stiffener at the same time.

2.1.3 Then use the smallest aperture of the fiber stripper to remove the coating layer.

2.2, Cleaning

Clean the bare optical fiber with a non-woven cloth dipped with anhydrous alcohol.

2.3, Cut

Put the clamping apparatus of the optical fiber and the fibers on the clamping socket of the optical fiber cleaver, and cut the fiber

2.4,Cold splicing

Insert the fiber into the body of the cold splicer

2.5,Testing

Use a fiber optic testing pen to test the connectivity status

2.6, Fiber optic cold splice looks simple, but it is actually technical work, the installation process also needs a lot of attention:

A, In the entire installation process of the connector, ensure cleanliness in every link.

B, Ensure the quality in the cutting end-face of the optical fiber

C. The end faces of the fiber on-site and the embedded fiber need to closely fit each other. This is the key to a successful termination.

D, The length of the on-site cutting fiber needs to be accurate, If the length is too short and fails to contact the pre-grinding short fibers. It will result in a gap between the end faces.

E, The length of the on-site cutting fiber needs to be accurate. Insert the fiber into the right place The fiber needs to be bent in a moderate way. Ensure the contact of the end face. Meanwhile, we should avoid the fibers being made overlong which will cause extra pressure on the end face and cause damage to the end faces.

3. The difference between cold splicing fiber and fusion splicing fiber

3.1, Fusion splicing

We need to use an optical fiber fusion splicer machine, a fiber optic cutter, to connect two fibers together, no other auxiliary materials are needed. The advantages are that the quality is stable., and splicing loss is small (about 0.05 to 0.08db), the disadvantages are the high cost of equipment and limited power storage capacity of the equipment. There are restrictions to field operations. In short, fusion splicing has better quality and low attenuation, but the operation is troublesome and requires a fusion splicer machine.

3.2. Cold Splicing

No need for too much equipment, a fiber optic cutter is the only tool needed, but each joint requires a fast connector, the advantage is easy to operate, and suitable for field operations, the disadvantage is the serious loss, "about 0.2 to 0.5dB per point cold splicer", In business and technical services areas, cold splicing has been restricted due to these disadvantages,

Secondly, the index-matching liquid is used in the cold splicer which will easily cause an aging problem.

4 In summary.

4.1, For the cost of a single fiber, cold splicing is much higher than fusion splicing.

4.2, The tools used for cold splicing are more convenient to carry, while fusion splicing requires carrying the fusion splicing machine which is very inconvenient.

4.3, The optical fiber after fusion splicing has a lower loss, while the fiber optic connector after the cold splicing process has a relatively more serious loss.